- Home

- |

- About

- |

- Services

- Civil Engineering and Drainage Plans

- Structural Engineering

- Mechanical Engineering

- Electrical Engineering

- Industrial Engineering

- Code, Energy Code, and Life Safety

- Fire Safety Engineering

- Energy Modelling

- Arc Flash Hazard Analysis

- Food Processing

- Shop Drawings, Steel, Precast Concrete

- Construction Management

- Agricultural Engineering

- Quantity Surveying

- Project Planning and Cost Estimating

- |

- Projects

- |

- News

- |

- Careers

- |

- Contact Us

Is Your Farm Ready for Rising Fuel Costs?

December 21, 2023

Are you concerned that your crop fertilization strategies will become unsustainable as a result of increased energy costs?

Throughout 2023, there have been clear indications of rising energy and fuel prices. Are you concerned that your crop fertilization strategies will become unsustainable as a result of increased energy costs? DGH has strategies, supported by years of industry experience and data from recent farm systems analysis, to help you reduce the economic risks to your farm and your livelihood related to climate change and rising fuel costs..

DGH clients have accessed as much as half-a-million dollars of federal funding using our services to gain valuable data to support funding applications for equipment upgrades. These projects are proven to decrease fuel use now and reduce risks related increased fuel costs in the future. The funding available will also significantly decrease any additional capital investment in equipment upgrades, and may even make energy efficient crop fertilization strategies more affordable than implementing more traditional solutions.

If the funding is available, why leave it on the table?

Some of you may already be picking up the phone or sending us an e-mail to find out how we can help you bring efficiencies to your operations and reduce risks related to rising operating costs. We also know that many of our clients will want to see the data before making that call. For those clients, we have outlined the findings of recent studies and reports we have completed for clients.

Agricultural producers have options available when considering methods for crop fertilization. Tank spreaders and drag hose systems are both effective methods for applying manure to your crops, and both methods require significant investments when purchasing equipment. DGH Engineering Ltd. (DGH) can provide analysis to help farmers decide what system is right for them. DGH offers Value Engineering to farmers by providing farm systems analysis to support agricultural business decisions. DGH's approach to Value Engineering may not reduce the total capital expenditure, but instead uses a data-driven approach to reduce operating costs, increase efficiency, and mitigate risks related to climate change. The cost to implement either manure application system is significant. The overall cost of ownership may make one system more appealing than the other.

Value Engineering and Farm Systems Analysis

Value Engineering is not about being cheap or frugal, rather it is a tool available to farmers ensure they receive the best value from their business decision. DGH's reports can be used for a producer's own decision-making process, to support a business case when securing financing, and to access government funding for agricultural operations, which can significantly reduce the capital cost of energy efficient equipment purchases.

DGH has recently worked with several farms to gather data and provide reports to support business cases for switching from tank spreaders to drag hose systems for manure application. The findings detailed in our reports overwhelmingly support the adoption of drag hose systems based on the reduction in fuel costs, tractor- and person-hours, and environmental impact. There is also potential for improved soil quality and a reduction in nitrogen loss, which reduces the need for purchasing additional fertilizer.

The majority of our recent field data has been collected to support the transition to drag hose systems from tank spreaders. Modern drag hose systems can be positioned over long distances, up to four miles, to distribute manure with relatively less effort and cost than using tank spreaders. The pumps that are currently used to deliver fertilizer from lagoon to field are diesel powered, but require significantly less fuel than trucks and tractors. Additionally, by injecting manure using drag hoses, farmers benefit from precise application of manure exactly where it is needed and decreased losses of nitrogen to air. Tilling and the associated costs to incorporate fertilizer into the soil are reduced or eliminated using this method.

The Numbers Don't Lie

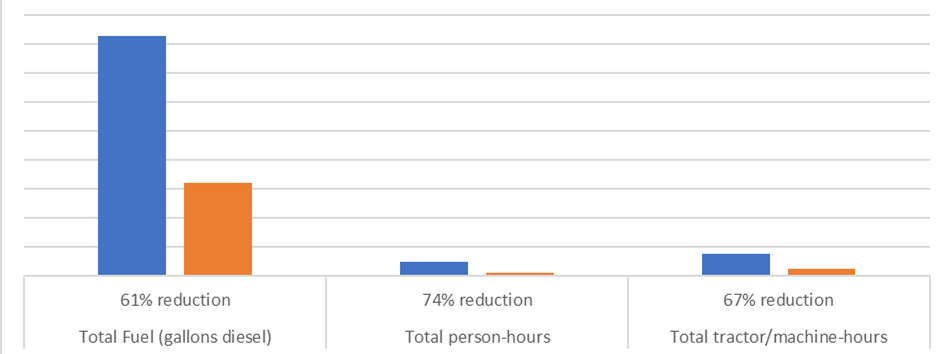

Based on DGH's analysis of several farms, a typical producer can gain significant efficiencies, decrease operating costs, and receive more value from capital investments by converting its operations to use manure injection. DGH's Farm Systems Analysis team has collected and analyzed data, and the numbers show that significant efficiencies can be gained by switching to a drag hose system, including:

- A 62%-67% reduction in tractor- and machine-hours, resulting in decreased maintenance costs

- A 72%-74% reduction in person-hours required for spreading manure and fertilizing crops

- A 48%-61% reduction in fuel consumption

- And a 52%-66% reduction in GHG emissions

While there are costs associated with converting a farming operation to use manure injection, these costs may be easily recouped over a short period of time through decreased maintenance and fuel costs. By injecting manure into the soil rather than using surface application, farmers can also decrease the total amount of manure required per acre and the need to purchase commercial fertilizers.

Some costs may be eligible for existing government funding through programs such as the Agricultural Clean Technology (ACT) Program or the Sustainable Canadian Agricultural Partnership (SCAP). DGH has completed reports for funding applications under these programs and assisted farmers with the application process to access funding.

These upgrades can future-proof your operation. By reducing fuel consumption and maintenance costs now, you are better prepared for sudden increases in fuel costs or other operating costs resulting from natural disasters, supply chain disruptions, or inflation in the future. Injection application of manure also mitigates the risks associated with both Greenhouse Gas (GHG) and odor emissions from farming operations, and eliminates the risk of contamination to water sources associated with traditional land application of manure.

Our Approach

Whether you plan on accessing funding for environmentally friendly upgrades to your farming operation, or are planning other upgrades that require significant capital investments, DGH can help you make the right choices for your operation. Our farm system analysis team includes Professional Agronomists and Agricultural Engineers that will coordinate all activities to ensure you have all of the information you need to make the best choices for you and your farming operations. Some activities that we will undertake to prepare a report custom-tailored to your operation include:

- Meet with owners to understand their needs

- Collect data about your operation with a simple questionnaire

- Review data to determine what additional information needs to be gathered through a site visit or using other existing data sources

- Conduct a site visit to review existing conditions, collect GPS or QGIS coordinates, and collect soil samples if soil sampling is necessary for your project

- Review all information collected

- Prepare and deliver reports to help farmers make informed decisions for capital investments and to support applications to funding sources

Many of our recent reports have focused on GHG emissions reduction and reducing diesel consumption, but DGH has a long history of Engineering and Consulting for agricultural operations. DGH can assist with permitting, barn design, and other capital project planning needs. Our in-house team can work with you from the planning stage to the completion of your project.